No products in the cart.

Wood Fiber Insulation

HOW CAN GSWRAP HELP WITH THE STRUCTURE OF YOUR HOME?

Building Passive House, for sure changes the structure of your home. While building Passive House, we can offer you our Wood Fiber Boards that will give you the best possible insulation on the market.

In today’s blog posts — we would like to share a quick interview, found on the passive house website, with Edward Lowes.

Here it goes.

1. What is the component certification process like? What are the prerequisites for getting a component certified?

These are just some of the questions that the new series “iPHA Q&A with PHI” has answered. Once a month, the iPHA Team sits together with experts from different departments at the Passive House Institute to hear about the work they do, what they offer and how you can make the most of those offerings.

Missed the last episode? In this new blog series, we will showcase the highlights of what was discussed during the past sessions. Make sure to watch the full presentation below if you want to get every detail!

On December 9, the second iPHA Q&A with PHI session focused on component certification. It featured a presentation by Edward Lowes, a Component Certifier at the Passive House Institute. Edward has a background in architecture and is currently pursuing professional registration as a facade engineer. His work at the Passive House Institute focuses on the certification of opaque and transparent components for manufacturers all over the world.

Component certification in a nutshell

Generally speaking, certified components can be divided into three categories:

- Transparent components (windows, entrance doors, curtain and wall systems)

- Opaque components (construction systems, wall-, roof- and floor- systems)

- Heating, ventilation and air conditioning systems (HVAC systems)

The main purpose of component certification is to optimise the process of energy balance calculation by using key values certified by the Passive House Institute.

2. What are the benefits of component certification?

The Passive House Institute’s component certification seal is the mark of an extremely high quality product in relation to its contribution to achievement of the Passive House standard. PHI certification ensures the quality of energy performance data through third party, independent review and makes the component’s performance data available for use in designPH and PHPP. Every component, after being certified, is also listed with its characteristics in the component database, making it stand out to building professionals from other products on the market.

The benefits of certification also apply to building designers, who can be confident that the component values they are using are accurate. This also helps streamline the building certification process, as these values will be immediately accepted, with minimal further information needed. The vast range of certified components also allows building designers to find the right product for their design and budget.

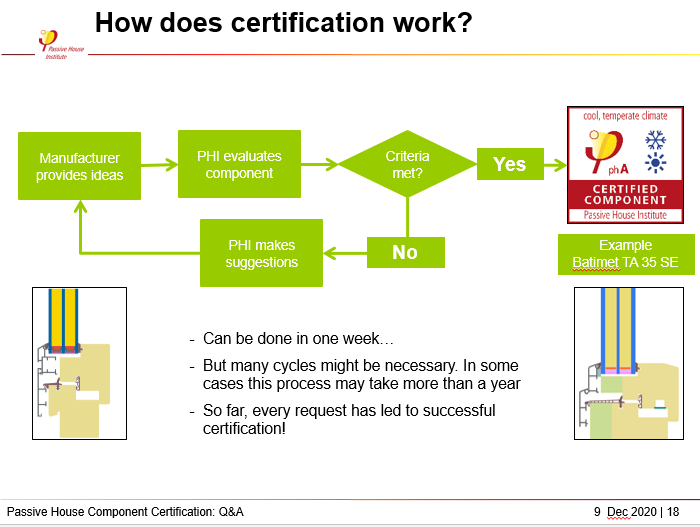

3. How does the certification procedure work?

The first step of component certification is for the manufacturer to provide the Passive House Institute’s Component Certification team with the design and specifications of their product. The team then begin evaluating the component, including performance testing. Window components and construction systems, for example, are tested mostly using software-based simulations, whereas airtightness systems are tested in the Passive House Institute laboratory. Once the results are obtained, they are compared with the PHI component criteria. If the criteria are met, the component is ready to be certified. If not, the certification team provides the manufacturer with suggestions on how the product could be adapted before going through a review. The length of this process may vary based on the complexity and type of component, ranging from a week to a year.

4. What is analysed during component certification?

In the case of windows, the certifier looks at the component’s thermal conductivity and carries out FEM thermal modelling (Finite Element Method modeling) to ISO 10211 and calculations to the window product standard ISO 10077-2 to find out its Uw-value (W/m²K). Other types of transparent components may require additional tests. This is the case of entrance doors, which also require airtightness testing to EN 12207.

For construction systems the certification requirement process is similar. Here, the design details are checked to make sure that there is a robust airtightness strategy, one of the principles of the Passive House Standard. As with the transparent components, the FEM thermal modelling to ISO 10211 is carried out, but in this case, the component must be thermal bridge free and meet U-values and hygiene requirements according to the respective climate zone.

The process of certification for heating, ventilation and air conditioning systems includes a review of third party test data and a comparison of the results against the criteria for e.g. comfort (supply air temperature); efficiency (heat and electrical); airtightness; and, for example, water heating efficiency.

5. What are the component certification criteria?

The Passive House Institute’s website has a dedicated section with all the criteria available based on the type of component, totalling 15 criteria documents. The criteria document for air source heat pumps is available upon request, as this is updated frequently and it is essential that the manufacturers are supplied with the latest version. During the recording of the session, Edward led the audience through some criteria documents, highlighting the important features and values and showing certification examples.

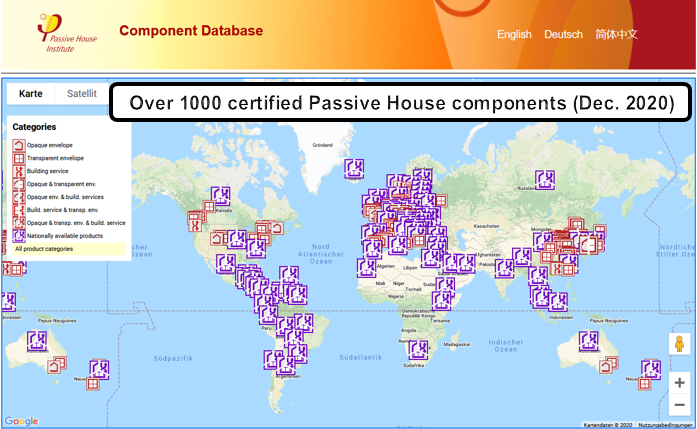

6. Which components have been already certified?

Worldwide, the market for highly-energy-efficient buildings is growing rapidly, and with it the need for reliable, high-performance components. As a result, the Passive House Institute has received an increasing number of highly-energy efficient components to certify according to their international criteria in order to meet comfort and indoor air quality criteria. All certified components are listed with full details in the component database. In order to simplify the component search, the database offers the possibility to search for components based on the type or location. By looking at the map of certified components, users can easily find components available in their area. During the session, Edward led the audience through the database and showed some of the certified components that can be found via the map!

Q&A Session highlights

Wondering what the most interesting questions from the session were? Here is a summary with time stamps to help you find the detailed answers in the video recording.

- (31:24) Why is airtightness not clearly stated in the certificate? Are there targets for airtightness performance? Yes, there are targets for airtightness performance. These are always available in the criteria documents. Specifically, if we are talking about transparent components, the targets are different based on the type of component. For door certification, these are a requirement, whereas, for windows, they are only a requirement for window system certifications.

- (33:00) Can you discuss the process of component certification for a volumetric modular project versus certifying it as a building? Modular buildings tend to be quite small (think ‘tiny homes’) and in terms of meeting the Passive House Standard, the smaller the building, the more difficult it can be to meet the efficiency standard required because the heat loss area is higher in relation to the volume of the building in such buildings. This means that theoretically, in order to reach the same level of efficiency, one would need to add more insulation than typical for Passive House buildings. When manufacturers get in touch to certify their small building modular air construction systems, we therefore recommend that a further analysis using designPH and PHPP be performed to see if it is possible to achieve the Passive House Standard using the construction system at the proposed module size.

- (35:16) Are there any major changes planned for 2021 in the certification processes and parameters, particularly in windows and door systems? No major changes are planned in 2021, at least to the component certification processes. The most recent update saw the addition of moisture criteria for construction system certification.

- (36:57) Is there any chance we’ll see embodied energy targets for components and products in the future? This is an important and frequently discussed topic and the Passive House Institute is well aware that certain components are more energy intense and have a greater environmental impact than others. Currently, the Passive House Standard is reducing the energy demand in operation, thus reducing operational energy, which makes up the majority of energy-use in a building over its lifecycle. At the moment, embodied energy is not factored into calculations. However, future cooperation with other certification systems that look at embodied carbon as well may be possible.

- (39:40) I am interested in why there are PVC windows allowed, given PVC is on the Living and Building Challenge’s red list. PVC windows currently make up around over 50% of the market [this was 57,7 % in 2018, according to the AGPU], due mostly to their affordability. When it comes to reducing operational energy, PVC windows are effective because it is quite easy to make cost and energy-efficient PVC windows, but of course, we are aware of the embodied energy that such material implies and this is something that we want to look into more in the future. It should be noted, however, that the Passive House Standard is a building performance standard and does not prescribe particular building materials. Thus, construction and design professionals are free and indeed encouraged, to choose more sustainable and less embodied energy-intensive components, materials and approaches.

- (43:42) What is your favorite part of component certification? I really enjoy the FEM modeling (finite element method modeling), it is really interesting because sometimes unexpected results jump out at you and you get to look at what makes a real difference in terms of the energy performance of a particular product.

Any further questions. You can watch the interview below: